China Cheap Transmission Substation Suppliers – 35kV angular tower – X.Y. Tower

China Cheap Transmission Substation Suppliers – 35kV angular tower – X.Y. Tower Detail:

Our advantage

We hold expertise in the design and fabrication of transmission line tower that are successful in serving the requirements of electrical industries. These transmission line towers are manufactured as per the design requirements of our clients and are subjected to rigid quality inspection to ensure zero defects and optimum functionality.

●8000 Sq. Meters of Workshop with Cranes.

●Adequate Storage Yard and package palace.

●experienced Engineers and Qualified Workers.

●High Customer Retention Rate.

●Producing Quality Products at Competitive Rates Ensuring.

●Timely Deliveries.

Tower description

Transmission tower is a tall structure, usually a steel lattice tower, use to support an overhead power line. We render these products with the help of

diligent workforce having vast experience in this field. We go through detailed line survey, route maps, spotting of towers, chart structure and technique document while providing these products.

Our product covers the 11kV to 500kV while include different tower type for example suspension tower, strain tower, angle tower, end tower etc.

Additionally, we still have a vast designed tower type and design service to be offered while if clients have no drawings.

| Product name | Transmission line tower |

| Brand | XY Towers |

| Voltage grade | 33/35kV |

| Nominal height | 9-36m |

| Numbers of bundle conductor | 1-4 |

| High-low voltage on the same tower | up 33/35kV down 10kV |

| Wind speed | 120km/h |

| Lifetime | More than 30 years |

| Production standard | GB/T2694-2018 or customer required |

| Raw Material | Q255B/Q355B/Q420B/Q460B |

| Raw Material standard | GB/T700-2006,ISO630-1995;GB/T1591-2018;GB/T706-2016 or Customer Required |

| Thickness | angel steel L40*40*3-L250*250*25; Plate 5mm-80mm |

| Production Process | Raw material test → Cutting →Molding or bending →Verification of dimensions →Flange/Parts welding →Calibration → Hot Galvanized →Recalibration →Packages→ shipment |

| Welding standard | AWS D1.1 |

| Surface treatment | Hot dip galvanized |

| Galvanized standard | ISO1461 ASTM A123 |

| Color | Customized |

| Fastener | GB/T5782-2000; ISO4014-1999 or Customer Required |

| Bolt performance rating | 4.8;6.8;8.8 |

| Spare Parts | 5% bolts will be delivered |

| Certificate | ISO9001:2015 |

| Capacity | 30,000 tons/ year |

| Time to Shanghai Port | 5-7 days |

| Delivery Time | Usually within 20 days depends on demand quantity |

| size and weight tolerance | 1% |

| minimum order quantity | 1 set |

TESTS

X.Y. Tower has a very strict test protocol to ensure all products we fabricate is quality. The following process is applied in our production flow.

Sections and Plates

1. Chemical composition (Ladle Analysis)

2. Tensile Tests

3. Bend Tests

Nuts and Bolts

1. Proof Load test

2. Ultimate Tensile Strength test

3. Ultimate tensile strength test under eccentric load

4. Cold bend test

5. Hardness test

6. Galvanizing test

All the test data are recorded and will be reported to the management. If any flaws are found, the product will be repaired or scraped directly.

Brief introduction of Tower production process and technology.

1. Lofting

Computers are used to stake out in X.Y. Tower. Three-dimensional steel structure computer-aided design TMA software is adopted. The program has the characteristics of high accuracy, strong applicability, and intuitiveness. Using this technology can improve work efficiency and ensure lofting accuracy. According to the structural characteristics of iron attachments, our company has compiled the geometric size check program and drawing program of iron attachments. The program has the characteristics of high accuracy, strong applicability, and intuitiveness. Using this technology can not only improve work efficiency, but also ensure the accuracy of drawing.

2. Cut off

X.Y.Tower adopts large-scale plate cutting equipment, section steel cutting equipment and advanced automatic flame cutting equipment, which is fully capable of ensuring that the quality of steel cutting meets the requirements of national standards and relevant technical documents.

3. Bending

X.Y.Tower uses large-scale hydraulic equipment and self-developed professional bending molds for bending to ensure that the processing accuracy meets the requirements of the GB2694-81 standard and the tender technical documents.

4. Hole making

X.Y.Tower has the domestic advanced level CNC angle steel reduction automatic processing line and other professional stamping equipment and drilling equipment, and is fully capable of ensuring that the quality of the holes meets the standards and user requirements.

5. Cut corners

The angle cutting equipment developed by our company can cut various forms of angle steel, and can fully guarantee the accuracy of angle cutting.

6. Clean roots, shovel back, plan bevel

X.Y.Tower has domestic advanced level of planing equipment, especially the high-speed planer with a stroke of 3 meters, which is most suitable for processing large iron accessories for root removal, shoveling, and beveling workpieces. The processing accuracy can fully meet the relevant standards and Provisions of technical documents.

7. Welding

X.Y.Tower adopts the domestic advanced level of carbon dioxide gas shielded welding machine, and has technicians with welding qualification certificate to operate it to ensure the welding quality. In order to ensure the geometric dimensions of the welded parts, our company will use molds for butt welding. In order to ensure the stability of the welding, our company will use professional drying equipment and heat preservation equipment to dry and store the welding rod. Therefore, it is fully capable of ensuring that the welding quality meets the relevant standards.

Free prototype tower assembly service

prototype tower assembly is a very traditional but effective way to inspect whether the detail drawing is correct.

In some cases, clients still want to do prototype tower assembly to ensure the detail drawing and fabrication is OK. Hence, we still provide prototype tower assembly service for free to customers.

In prototype tower assembly service, X.Y. Tower makes commitment:

• For each member, the length, position of holes and interface with other members will be checked accurately for proper fitness;

• Quantity of each member and bolts will be carefully checked from the bill of materials when assembling the prototype;

• Drawings and bill of materials, sizes of bolts, fillers etc. will be revised if any mistake is found.

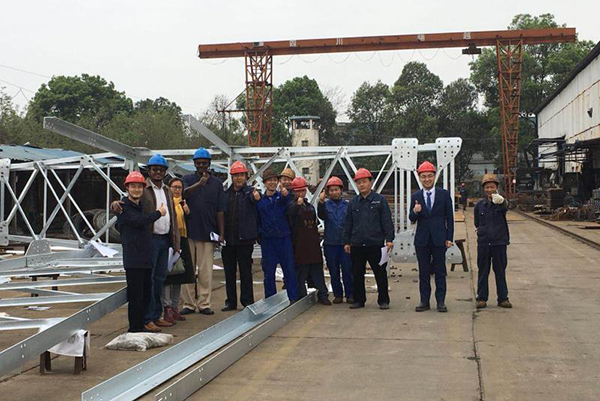

Customer visit service

We are so glad that our clients to visit our factory and inspect the product. It is a great chance for both sides to know each other better and strengthen cooperation.For our clients, we will receive you at Airport and provide 2-3 days accommodation.

Package and shipment

Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments.

All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.

Shipment

Normally, the product will ready in 20 working days after deposit. Then the product will take 5-7 working days to arrive at Shanghai Port.

For some countries or regions, like Central Asia, Myanmar, Vietnam etc., China-Europe freight train and carriage by land may be two better options of transportation.

Product detail pictures:

Related Product Guide:

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for China Cheap Transmission Substation Suppliers – 35kV angular tower – X.Y. Tower , The product will supply to all over the world, such as: Guatemala, Nigeria, Cape Town, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!