110kV Strain Tower For Electric Transmission

TRANSMISSION LINE TOWER

110kV ANGLE STEEL STRAIN TOWER

XYTOWER Strain tower refer to one tall structure, usually a single pole or pipe structure, used to support an overhead power line. They are used in middle-voltage AC and DC systems, such as 35KV, 66KV, 69KV, 110KV, 132KV, 220KV, 230KV, and come in a wide variety of shapes and sizes.Strain pole was located between every three or four suspension tower to pull the conductors which are re-tied in strain tower insulators.

XYTOWER fabricates every structure strain pole by solid steel legs and angle iron cross members & pipes. Structures can reach heights up to 40 meter, even higher. XYTOWER is one of the few manufactures who assemble a face of every tower section. This attention to quality may not be the cheapest process but it does insure every tower meets our high standards of quality. And it helps to reduce on-site construction cost due to mismatched assemblies.

After fabrication all strain poles are delivered to the galvanizing facility to be Hot DIP Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free towers.

DESIGN SPECIFICATION

|

Height

|

From 10M-100M or according to client’s requirement

|

|

Suit for

|

Electric Power Transmission and Distribution

|

|

Shape

|

Polygonal or Conical

|

|

Material

|

Normally Q235B/A36,Yeild Strength≥235MPa

|

|

Q345B/A572,Yeild Strength≥345MPa

|

|

|

As well as Hot Rolled coil from ASTM572, GR65,GR50,SS400

|

|

|

Power Capacity

|

110kV

|

|

Tolerance of the dimension

|

According to client’s requirement

|

|

Surface treatment

|

Hot-dip-galvanized following ASTM123, or any other standard

|

|

Joint of Poles

|

Slip joint, flanged connected

|

|

Standard

|

ISO9001:2015

|

|

Length of per section

|

Within 13M once forming

|

|

Welding Standard

|

AWS(American Welding Society)D 1.1

|

|

Production Process

|

Raw material test-cutting-bending-welding-dimension verify-flange welding-hole drilling-sample assemble-surface clean-galvanization or power coating /painting-recalibration-packages

|

|

Packages

|

Packing with plastic paper or according to client’s requirement

|

|

Life Period

|

More than 30 years, it is according to installing environment

|

|

Key Words

|

steel structure、power electric tower、steel tower、transmission line tower。steel lattice tower

|

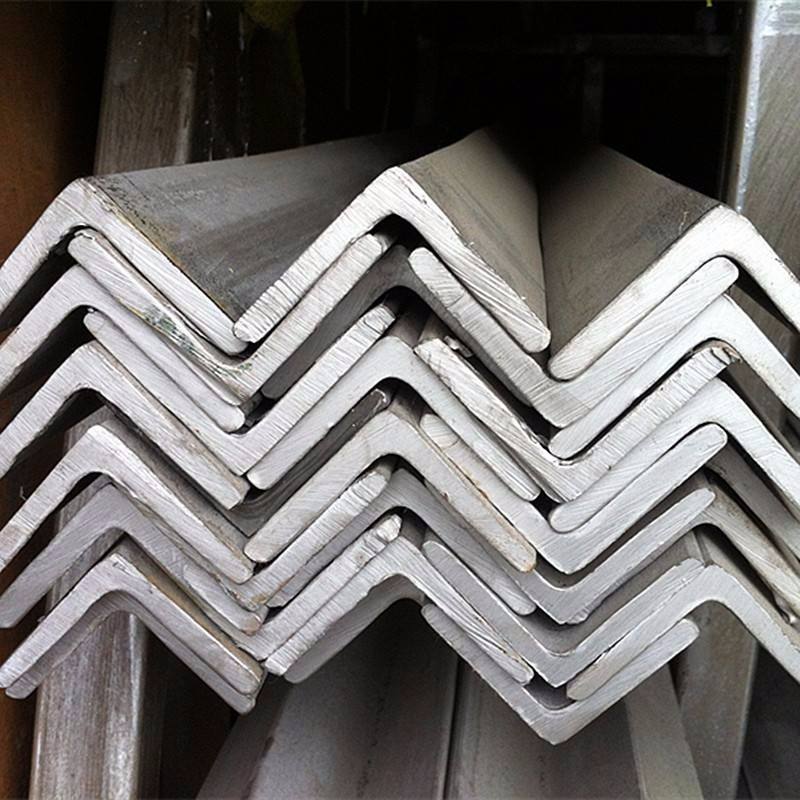

MATERIAL

angle steel is widely used in various architectural and engineering structure,such as house beam,bridge,transmission line tower,telecommunication tower,heavy transport machinery,ships,industrial furnace,reaction tower,container frame,warehouse shelves etc.

ADVANTAGE

1. Strict quality control system and abundant technical reserves have created world-class products.

2. The factory has completed tens of thousands of project cases so far, so that we have a wealth of technical reserves;

3. Facilitating supports and low labor cost make the product price have great advantages in the world.

4. With a mature drawing and drawing team, you can rest assured of your choice.

5. China Power Grid Certification supplier, you can safely choose and cooperate;

6. We are not only manufacturers and suppliers, but also your partners and technical support.

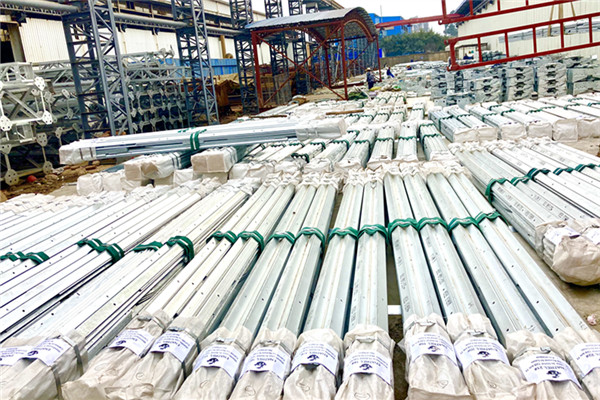

GALVANIZING

Quality of Hot-dip galvanizing is one of our strength, Our CEO Mr. Lee is an expert in this field with reputation in Western-China. Our team has vast experience in HDG process and especially good at handling the tower in high corrosion areas.

Galvanized standard: ISO:1461-2002.

PACKAGE

Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments.

All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.

More details please feel free to click below to CONTACT US!!!