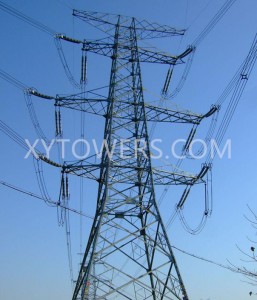

500kV Power Electric Transmission Tower

High-strength Customized Angle Transmission Steel Tower with Galvanization

Angle steel tower: It covers a relatively large area and is widely used in ordinary urban areas, suburbs, county towns, towns, rural areas, along traffic lines and other sites with low requirements for landscape and low antenna height.

Transmission Line Steel Tower & Substation Structure- Goods description and major parameters:

| No. | Description | Detailed Specification and Major design Parameters |

| 1 | Design Code | 1. Chinese National Standard:a. DL/T 5154-2002 Technical Regulation of Design For Tower and Pole Structures of Overhead Transmission Line

b. DL/T 5219-2005 Technical Regulation for Designing Foundation of Overhead Transmission Line 2. American Standard: a. ASCE 10-97-2000 Design of Latticed Steel Transmission Structures b. ACI 318-02 Building Code Requirement for Structure Concrete |

| 2 | Design Software | PLS and MS Tower, SAP2000, AutoCAD, STW, TWsolid, SLCAD etc |

| 3 | Design Loading | As per requirement and specification by Clients worldwide. |

| 4 | Load test/destructive test | We can arrange it by Government authority if it is necessary and the cost of such kind of test is separately from the tower pricing. |

| 5 | Voltage | 33KV, 66/69KV, 110KV, 220KV/230KV, 330KV, 380/400KV, 500KV, 750KV Transmission Line |

| 6 | Hot-dip galvanization | ISO 1461-2009, ASTM A123 |

| 7 | Steel Grade | 1. High strength low alloy structural steel: Q420B which is equivalent with ASTM Gr602. High strength low alloy structural steels: Q355B which is equivalent with ASTM Gr50 or S355JR

3. Carbon Structural Steel: Q235B which is equivalent with ASTM A36 or S235JR |

| 8 | Bolts and Nuts | Mainly ISO 898 grade 6.8 and 8.8 bolts for Both Chinese, ISO and DIN standard |

| 9 | Tower Type | Angular Towers, Tubular Towers, Guyed Mast, Monopole Tower |

| 10 | Tower Type | Suspension Tower, Tension Tower, Dead Tower, Substation Structure |

| 11 | Warranty | Tower structures: 10 years |

| 12 | Return Period | 50 Years |

| 13 | Transportation | We are very close to the biggest port in the world which is our advantage for sea transportation. |

| 14 | Quality Control | Follow ISO 9001 system and strictly QC inspection for raw material, prototype assembly test, galvanization test and pre-shipment inspection for the both quantity and qualityWe treat the quality first and 100% inspection ratio. |

XYTOWER :

professional steel towers manufacturer and exporter

XYTOWER is a company specialising in manufacturing various galvanized steel structures including Lattice Angle Tower, Steel Tube Tower, Substation Structure,telecommunication Tower,RoofTop Tower, and Power Transmission Bracket used for transmission lines up to 500kV.

XYTOWER focus on the production of hot dip galvanized steel towers for 15 years, have own factories and production lines, with an annual product of 30000 tons, sufficient supply capacity and rich export experience!

The 10kV-500kV angle lattice steel tower designed and processed by the company have passed the type test (tower structure load test) at one time. Our goal is to strive to provide customers with satisfactory products and services.

PRODUCT SHOWS:

MATERIALS:

In order to ensure the product quality, we start from the procurement of raw materials. For the raw materials, angle steel and steel pipes required for product processing, our factory purchases the products of large factories with reliable quality throughout the country. Our factory also needs to inspect the quality of raw materials to ensure that the quality of raw materials must meet national standards and have the original factory certificate and inspection report.

ADVANTAGES:

1. An authorized supplier in Pakistan, Egypt, Tajikistan, Poland, Panama and other countries;

China Power Grid Certification supplier, you can safely choose and cooperate;

2. The factory has completed tens of thousands of project cases so far, so that we have a wealth of technical reserves;

3. Facilitating supports and low labor cost make the product price have great advantages in the world.

4. With a mature drawing and drawing team, you can rest assured of your choice.

5. Strict quality control system and abundant technical reserves have created world-class products.

6. We are not only manufacturers and suppliers, but also your partners and technical support.

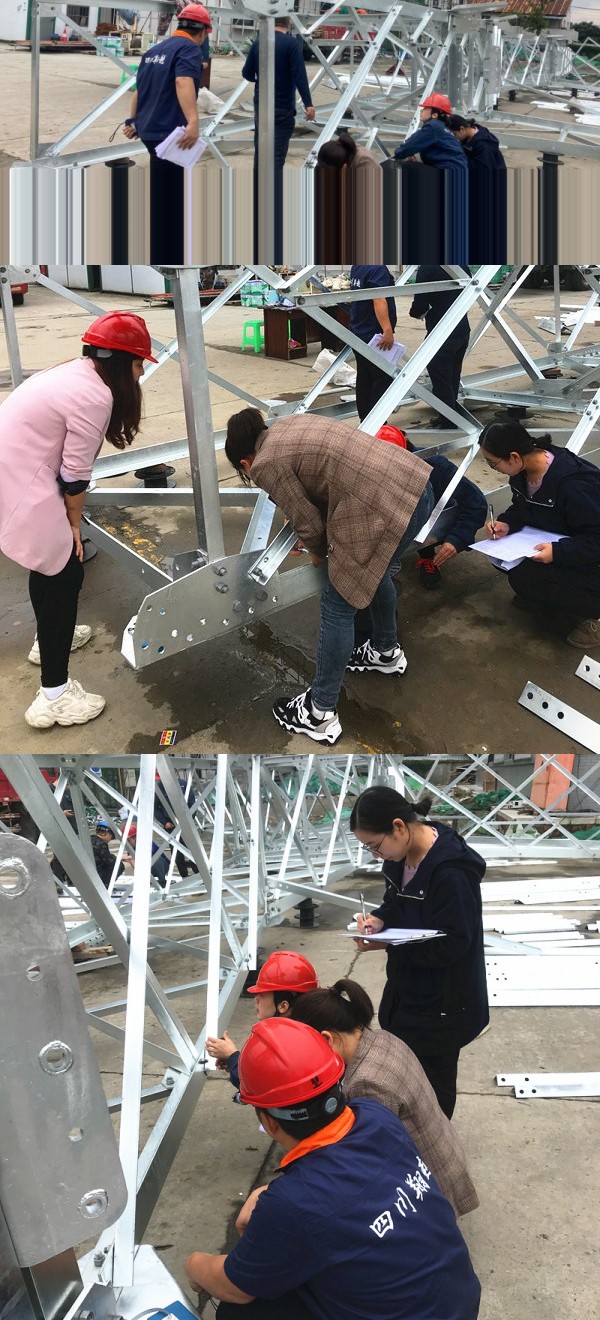

ASSEMBLY & TEST OF STEEL TOWERS:

After the production of the iron tower is completed, in order to ensure the quality of the iron tower, the quality inspector shall conduct assembly test on it, strictly control the quality, strictly control the inspection procedures and standards, and strictly inspect the machining dimension and machining accuracy according to the provisions of the quality manual, so as to ensure that the machining accuracy of parts meets the standard requirements.

Other Services:

1. Customers may employ a third-party testing organization for tower testing.

2. Accommodation can be arranged for customers visiting the factory for tower inspection.

Myanmar electric tower assembly

East Timor telecom tower assembly

Nicaragua electric tower assembly

Assembled steel tower

HOT DIP GALVANIZATION:

After assembly and testing, the next step is hot-dip galvanizing. This process enhances the appearance of the steel tower, prevents rust, and extends its life.

Our company has its own galvanizing factory, a skilled team, experienced teachers, and strictly abides by the ISO1461 galvanizing standard.

Below are our galvanizing parameters for your reference:

|

Standard

|

Galvanized standard: ISO:1461

|

| Item |

Thickness of zinc coating

|

| Standard and requirement | ≧86μm |

| Strength of adhesion | Corrosion by CuSo4 |

| Zinc coat not be stripped and raised by hammering | 4 times |

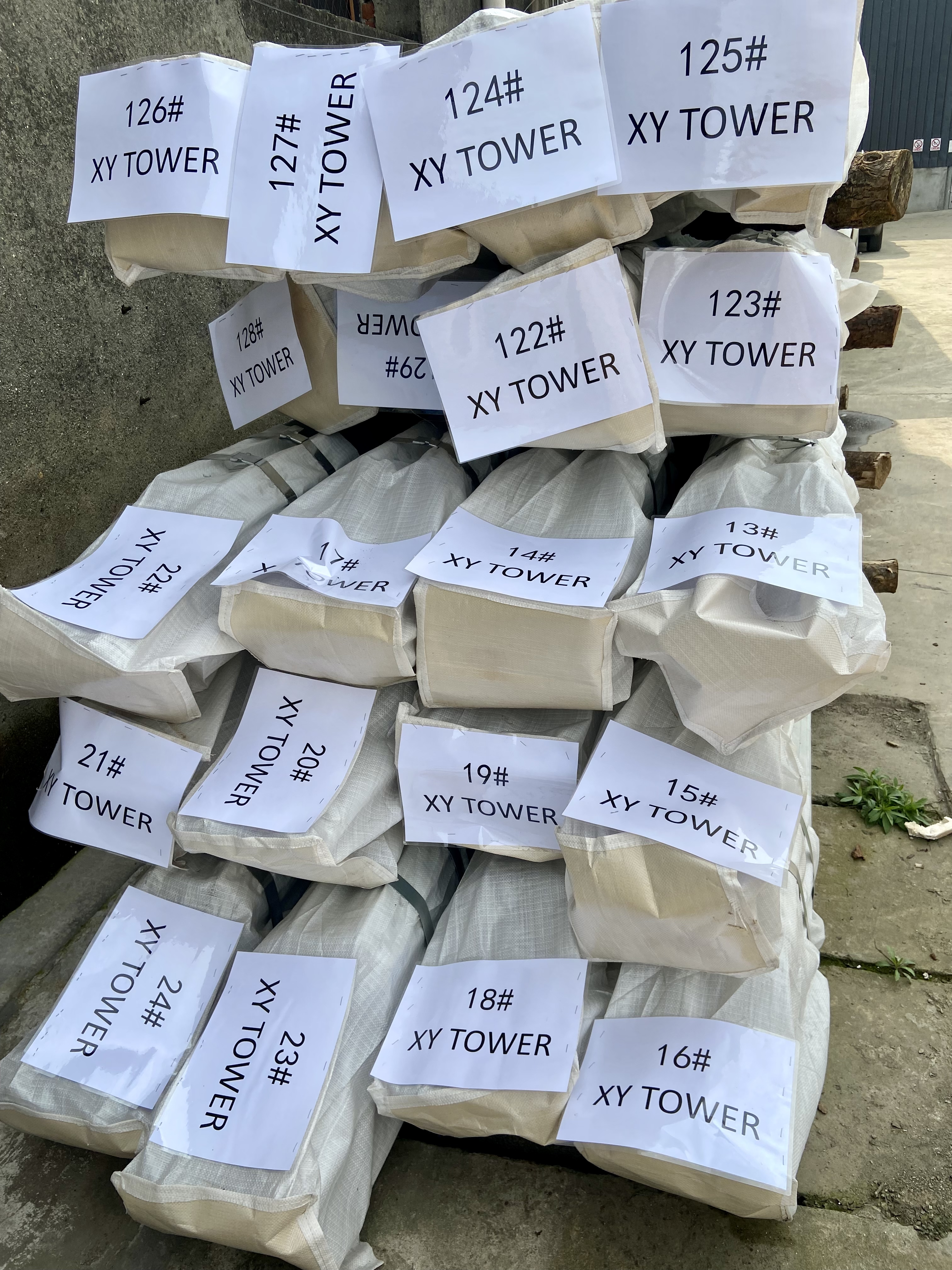

PACKAGE:

After Galvanization,we start to package,Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments.

All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.