Deformed Steel Rebar

Hot Sale Deformed Steel Rebars

|

Product Name

|

Steel Rebar

|

|

Material

|

HRB335 HRB400 HRB400E HRB500

|

|

Surface treatment

|

Galvanied

|

|

Keyword

|

High Strength Rebar Steel

|

|

Shape

|

Round Deformed Steel Bar

|

|

Size

|

Accept Customerized

|

|

Specifications

|

Diameter(6-50mm):6mm,8mm,10mm,12mm,16mm,20mm,22mm,25mm,28mm,32mm,40mm,50mm Or OEMLength:6m-12m as your required

|

|

Grade

|

Grade40 Grade60

|

|

Inspection

Methods |

Tensile testing

(1) Tensile test method: GB/T228.1-2010, JISZ2201, JI SZ2241, ASTMA370, 1497, BS18, etc; (2) Bending test method: often use standard test methods have GB/T232-88, YB/T5126-2003, JISZ2248, ASTME290, ROCT14019, etc. |

|

Technique

|

Hot Ribbed Steel Rebar

|

|

Packing

|

Standard Seaworthy Packing

|

|

Usage

|

Rebar is widely used in building, bridge, road and other civil engineering construction. From highway, railway,bridge,

culvert,tunnel, flood control, dam and other public facilities, to the building foundation, beams,columns, walls, plates, screw steel are indispensable structural materials. With the deepening of urbanization,the demand for rebar is strong for infrastructure construction and the booming development of real estate. |

|

Delivery time

|

15~21days

|

Workshop Show

XYTOWER is a company specialising in manufacturing various galvanized steel structures including Lattice Angle Tower, Steel Tube Tower, Substation Structure,telecommunication Tower,RoofTop Tower, Light Pole and Power Transmission Bracket used for transmission lines up to 500kV.

XYTOWER focus on the production of hot dip galvanized steel towers for 15 years, have own factories and production lines, with an annual product of 30000 tons, sufficient supply capacity and rich export experience!

Company Profile

* Manufacture equipments(more than 100 sets):

16-meter CNC bending machines 、16-meter Laser cutting machines、Automatic angle steel lines、Punching machine handline、CNC Hydraulic Punching、Welding machines,etc.

* Test Equipments:

Digital hydraulic universal 、Ultrasonic flaw detector、 Eddy current analyzer, Weld flaw detection cell, Coating thickness gauge,etc.

* Design Software:

Telecommunication tower:ANSI/TIA-222-G-2.

Electric monopole:Beijing Daoheng software.

* Following Chinese Manufacture Standard:

Angular steel: GB/T2694 , Monopole :DLT646.

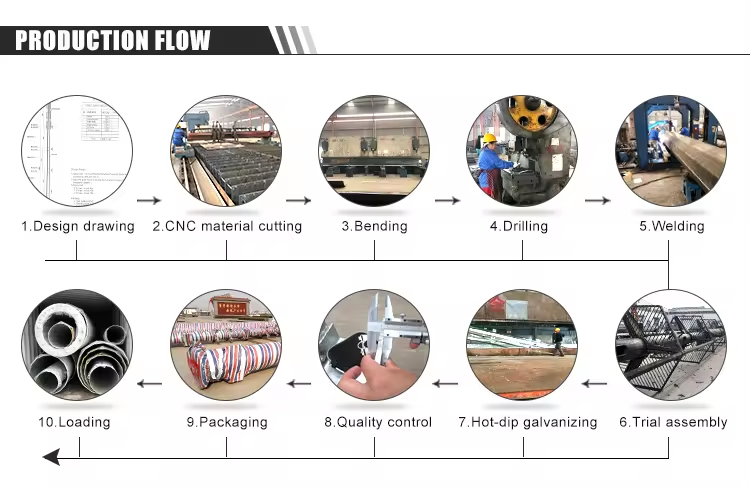

Product Flow

Production Process: Rew material test → Cuttingj →Molding or bending →Welidng (longitudinal )→Dimension verify→Flange welding →Hole drilling→Calibration → Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packages

Packing & Shipment

1)All sea shipping packing with Pallet,no throw,no broken

2)Paypal,TT Bank wire,L/C,Western Union,Trader-assurance

3)Samples 2-3 days,bulk order 5-10 days

Leave Your Message for More Details,Contact Now!!!