Transmission Line Steel Lattice Tower

Who We Are

Our Team

⦁ Engineers team with average 20 years of work experience

⦁ One stop professional service is provided for overseas market

Our Story

⦁ a Chinese integrated electrical power company, mainly offers various electrical products to domestic and oversea energy utility companies and high-energy-usage industrial customers.

⦁ Specialize manufacturer in the field of 10kV-500kV transmission line tower/pole for electricity transmission and distribution, telecommunication tower/pole, substation structure, and steel fittings etc.

Tension Tower vs Corner Tower

The tension tower is mainly considered from the stress. It should not only bear the gravity load of the conductor, ground wire and line fittings of the transmission line and the additional load caused by external conditions, but also bear the tensile force along the line to support the longitudinal unbalanced tension caused by accidental disconnection and the load during construction and maintenance.

The corner angle tower is mainly considered from the purpose. Sometimes it is necessary to change the direction according to the line direction. The tower used to change the line direction is called the angle tower. However, the tension tower can be used at a small corner below 5 degrees. After changing the parameters, it can be used instead of the corner tower. When the line corner is greater than 5 degrees, it must be designed according to the corner tower.

Corner Tower Imformation

| Product Name | Corner Tower |

| Voltage Grade | 220kV |

| Raw Material | Steel Q235,345,A36,GR50 |

| Surface Treatment | Hot dip galvanized |

| Galvanized Thickness | Average Layer Thickness 86um |

| Bolts | 4.8;6.8;8.8 |

| Certificate | GB/T19001-2016/ISO 9001:2015 |

| Lifetime | More than 30 years |

| Manufacturing standard | GB/T2694-2018 |

| Galvanizing Standard | ISO1461 |

| Raw Material Standards | GB/T700-2006, ISO630-1995, GB/T1591-2018;GB/T706-2016; |

| Fastener Standard | GB/T5782-2000. ISO4014-1999 |

| Welding Standard | AWS D1.1 |

Material

Hot dip galvanizing is one of the most effective means to delay the environmental corrosion of iron and steel materials. It is to immerse the cleaned and activated iron and steel products in molten zinc solution, and coat the surface of iron and steel products with zinc alloy coating with good adhesion through the reaction and diffusion between iron and zinc.

Our galvanizing standards are as follows:

| Item | Thickness of zinc coating |

| Standard and requirement | ≧86μm |

| Strength of adhesion | Corrosion by CuSo4 |

| Zinc coat not be stripped and raised by hammering | 4 times |

| Galvanized standard | ISO:1461-2002 |

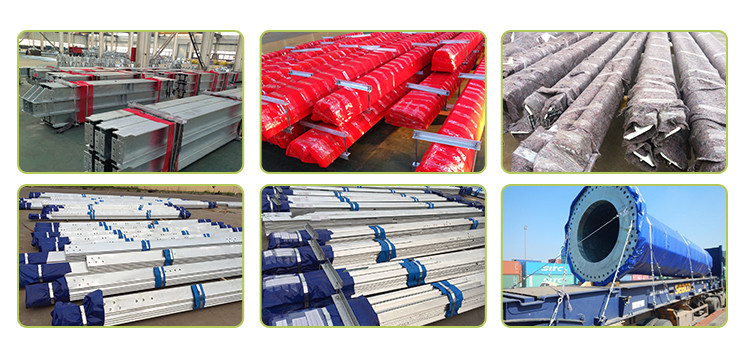

Delivery

Our company has a perfect logistics service system. Each of our products will be divided into parts suitable for transportation, which will be carefully packaged and sent to the port or the place designated by the buyer. The packing of the products is very easy to disassemble and protect the goods from damage.

Leave Your Message for More Details,Contact Now!!!