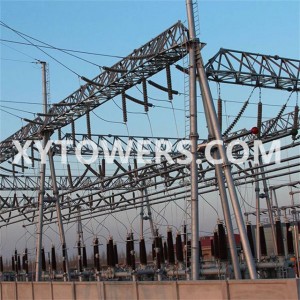

High Voltage 220KV Transformer Substation Structures

Function of Substation:

-----------------------------------

Electric substation refers to the place where voltage and current are transformed, electric energy is received and distributed in the power system.

The main function of substation is to connect the power grids with different voltage levels, and complete the task of power transmission and distribution through transmission lines.

Generally speaking,The power generated by the power plant is boosted to the power grid through the step-up substation. After the power grid sends the power to the destination, it is depressurized and distributed to users through the step-down station.

steel tube combination tower substation architecture for electric equipment supplies

Quick details:

Transformer substation steel structure is the important component for power transmission. The galvanized steel is the most common type raw material.

Usually a substation structure consits of three parts: dead-end structures(H frame and A frame), static poles and bus supports/equipment stands.

Kinds of Substation Structure

-----------------------------------

Item Specifics

-----------------------------------

|

Height

|

From 10M-100M or according to client’s requirement |

| Suit for | Electric Power Transmission and Distribution |

| Shape | Polygonal or Conical |

|

Material

|

Normally Q235B/A36,Yeild Strength≥235MPa |

| Q345B/A572,Yeild Strength≥345MPa | |

| As well as Hot Rolled coil from ASTM572, GR65,GR50,SS400 | |

| Power Capacity | 10kV to 500kV |

|

Tolerance of the dimension

|

According to client’s requirement

|

|

Surface treatment

|

Hot-dip-galvanized following ASTM123, or any other standard |

| Joint of Poles | Slip joint, flanged connected |

| Standard | ISO9001:2015 |

| Length of per section | Within 13M once forming |

| Welding Standard | AWS(American Welding Society)D 1.1 |

| Production Process | Raw material test-cutting-bending-welding-dimension verify-flange welding-hole drilling-sample assemble-surface clean-galvanization or power coating /painting-recalibration-packages |

| Packages | Packing with plastic paper or according to client’s requirement |

| Life Period | More than 30 years, it is according to installing environment |

To get professional quotations, please email to us or submit the following sheet, we will contact you in 24 hours! ^_^