Guyed Mast Tubular Steel Tower

What We Do

⦁ A Chinese integrated electrical power company, mainly offers various electrical products to domestic and oversea energy utility companies and high-energy-usage industrial customers.

⦁ Specialize manufacturer in the field of transmission line tower/pole for electricity transmission and distribution, telecommunication tower/pole, substation structure, and steel fittings etc.

Our Vision

- ⦁ To be EFFECTIVE in performing our duties and providing services to internal and external customers.

For telecom towers in various situations, you are welcome to come for customized consultation, professional design team and one-stop service are provided!

We need customers to provide the following basic parameters: wind speed, height,antenna number, antenna area

| Product name | Telecom Guyed Tower |

| Raw Material | Q235B/Q355B/Q420B |

| Surface treatment | Hot dip galvanized |

| Galvanized thickness | Average layer thickness 86um |

| Painting | Customized |

| Bolts | 4.8;6.8;8.8 |

| Certificate | GB/T19001-2016/ISO 9001:2015 |

| Lifetime | More than 30 years |

| Manufacturing standard | GB/T2694-2018 |

| Galvanizing standard | ISO1461 |

| Raw material standards | GB/T700-2006, ISO630-1995, GB/T1591-2018;GB/T706-2016; |

| Fastener standard | GB/T5782-2000. ISO4014-1999 |

| Welding standard | AWS D1.1 |

| EU standard | CE : EN10025 |

| American Standard | ASTM A6-2014 |

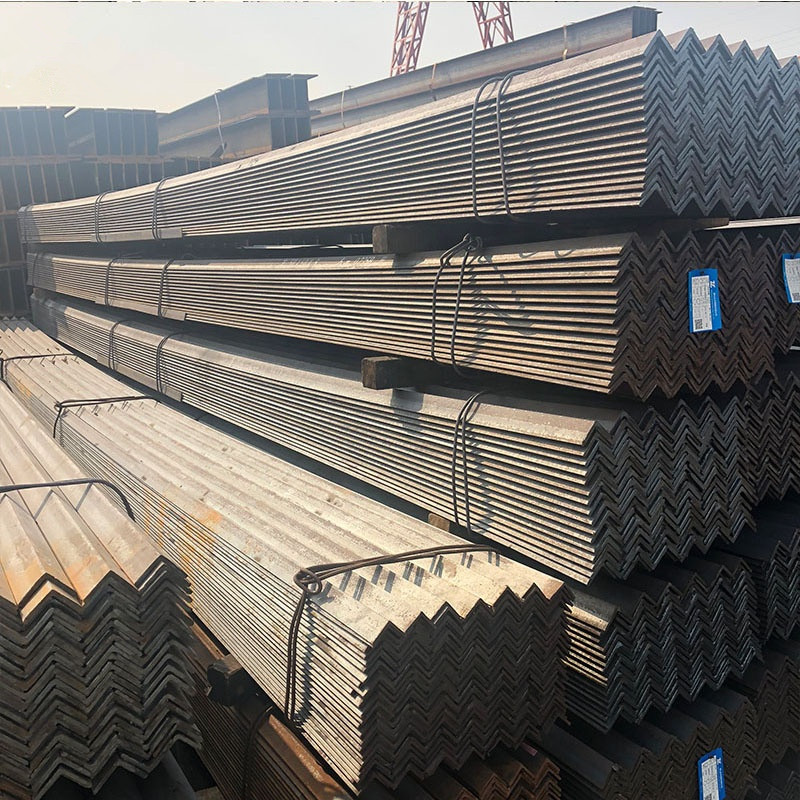

In order to ensure the product quality, we start from the procurement of raw materials. For the raw materials, angle steel and steel pipes required for product processing, our factory purchases the products of large factories with reliable quality throughout the country. Our factory also needs to inspect the quality of raw materials to ensure that the quality of raw materials must meet national standards and have the original factory certificate and inspection report.

After the production of the iron tower is completed, in order to ensure the quality of the iron tower, the quality inspector shall conduct assembly test on it, strictly control the quality, strictly control the inspection procedures and standards, and strictly inspect the machining dimension and machining accuracy according to the provisions of the quality manual, so as to ensure that the machining accuracy of parts meets the standard requirements.

Other Services:

1. The customer can entrust a third-party testing organization to test the tower.

2. Accommodation can be provided for customers who come to the factory to inspect the tower.

After assembly & test, the next step will be carried out: hot dip galvanizing, which aims at beauty, rust prevention and prolonging the service life of the steel tower.

The company has own galvanizing plant, professional galvanizing team, experienced galvanizing teachers for guidance, and processing in strict accordance with ISO1461 galvanizing standard.

The following are our galvanizing parameters for reference:

|

Standard

|

Galvanized standard: ISO:1461

|

| Item |

Thickness of zinc coating

|

| Standard and requirement | ≧86μm |

| Strength of adhesion | Corrosion by CuSo4 |

| Zinc coat not be stripped and raised by hammering | 4 times |

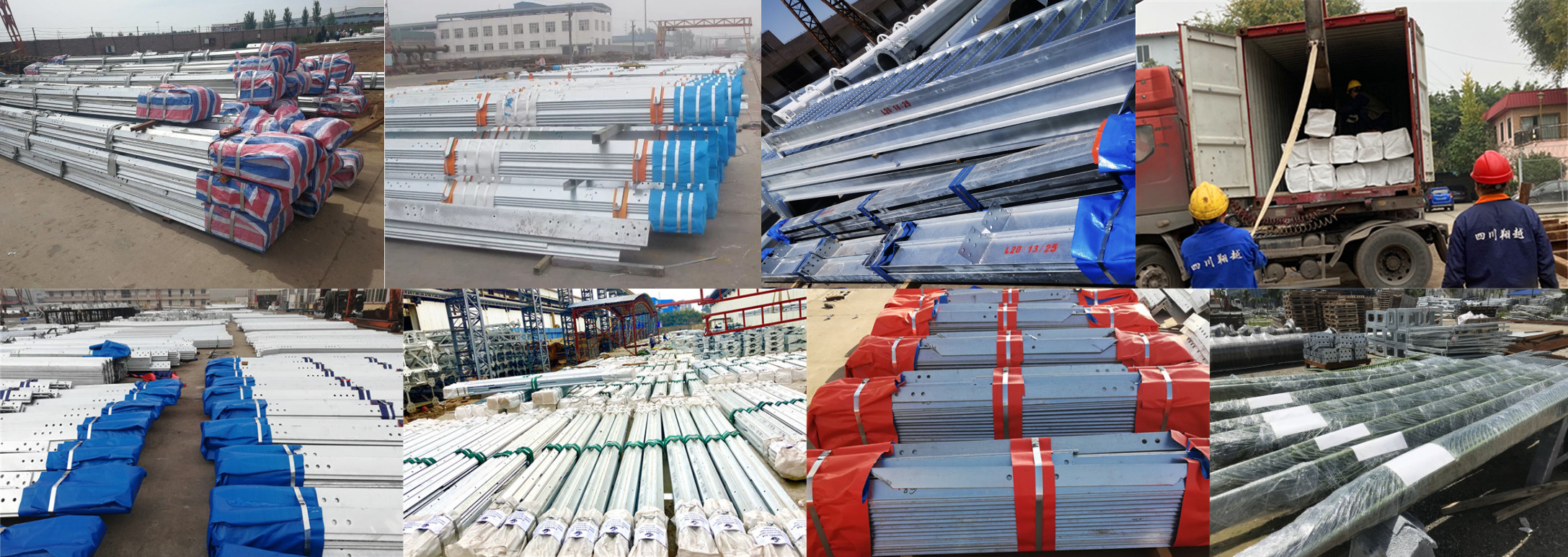

After Galvanization,we start to package,Every piece of our products is coded according to the detail drawing. Every code will be put a steel seal on each piece. According to the code, clients will clearly know a single piece belong to which type and segments.

All the pieces are properly numbered and packaged through the drawing which could guarantee no single piece missing and easily to be installed.